2. Pros & Cons of Various Sharpening Devices

The number of sharpening devices can be overwhelming. Here are some of the pros and cons of the various types of sharpening devices. For those looking for a way to sharpen knives, hopefully, this article will give you a little guidance on what kind to purchase.

Ceramic & Diamond Rods

Sharpening rods are two rods set in a base at a specific angle, 30 degrees for the ones I use. The rods can be round, square, or triangular - as long as the knife has a smooth surface to slide along. Many of these rods are made out of Alumina Ceramic. The material is a distant cousin of what your crock-pot is made of, but a much higher grade.

Sharpening Rods are my favorite way to maintain my edge. They are quick, easy to use, and easy to learn. There is a little bit of technique to them, but they are very easy to learn. Rods are limited in that they can only sharpen the preset angles, and more uncommon knives with special angles won’t benefit as much from a Rod Sharpener.

Pros

-

Easy to use & set up

-

Easy to learn

-

Excellent at quick maintenance and keeping your blades sharp

-

Relatively inexpensive (require less material)

-

Doesn't take off too much material

-

Easy-to-maintain rods

-

Can be useful on recurved blades as well as certain serrations such as:

-

The scalloped serrations of the Sea Skorpion

-

Cons

-

Has a set angle. It can't do custom angles

-

Often best used for edge maintenance, not ideal for heavy reprofiling. Slow if you need to remove a lot of material.

Angled Rod Sharpener Options

- A.G. Russell Ceramic or Diamond V-Rod Sharpener

- A.G. Russell Field Sharpener

- Spyderco Sharpmaker Triangle Sharpener - Capable of both 30 and 40-degree set angles.

- DMT Diamond-Vee Portable Sharpener

Conclusion

Because they are so easy, they are my preferred way to maintain my edge, and also my #1 recommendation for new knife users.

Watch this video of A.G. to see the Ceramic Rods in action.

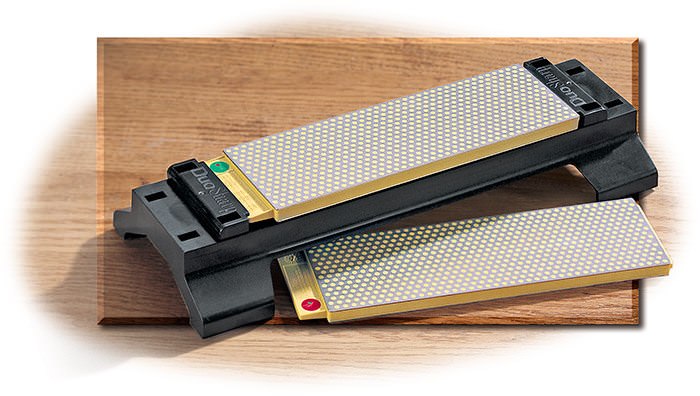

Bench Stones, Whetstones, & Sharpening Stones

When someone refers to a sharpening stone, a whetstone, or a Bench stone, they are usually referring to a flat block of dense material between 2 and 14 inches long used in the sharpening and shaping of metal tools, such as knives. These stones can be made out of a myriad of materials: natural stone, man-made stone, diamonds embedded on a block, alumina ceramic, and many other materials.

Pros

-

One of the most efficient ways to sharpen

-

One of the best ways to sharpen multiple tools, and lots of them

-

-

Fast - One of the faster manual ways to sharpen tools (depending on the stone material)

-

Flexible in use. You can sharpen many different tools at many different angles since it is all free-hand sharpening.

Cons

-

Difficult skill to master - takes a lot of practice

-

Requires a steady hand

-

Certain stones & materials can be very expensive

Conclusion

In my opinion, mastering free-hand bench stone sharpening is well worth your time if you work often with sharp tools.

Learn how to use Bench Stones here.

Guided Sharpening Systems

Very similar in exercise to bench stones, guided sharpening systems enjoy many of the benefits of bench stones while reducing the time it takes to learn the skill by using pre-set angles. As shown in the picture, the system guides your knife at the appropriate angle along the stone.

Pros

-

Very efficient sharpening

-

Easier to learn than free hand

-

Very flexible with many angle options

-

Most systems come with all the grits you need to get started

Cons

-

Not quite as flexible as free hand

-

It's difficult to sharpen larger tools like chisels, large knives, axes, etc.

-

-

Still requires some skill and knowledge.

Options

DMT Aligner Guided System

DMT Diafold Magna-Guide Sharpening System

Wicked Edge WE60 Sharpener

Conclusion

Guided systems make an excellent halfway point. There are many knife users who use the guided system and are completely satisfied with their sharpening skills and results. If you aren’t quite ready to make the leap for full free-hand stone sharpening but want to be able to do more than get "somewhat" sharp or edge realignment, sharpening systems are an excellent way to go.

Pull Through Sharpeners

Pull Through sharpeners takes two pieces of hardened material (typically Tungsten Carbide) and places them in an intersecting V shape at a set angle. To use, you pull the knife through the V. Be sure to go at a steady pace and put even pressure on the blade during the whole movement. Do not put too much pressure or the blade will skip and create a jagged edge.

The V-sharpener has one major inherent flaw. It is very difficult to maintain even pressure throughout the entire pull, which usually causes a straight edge to become a recurved edge by taking away too much material at the heel of the blade and not enough for the rest of the blade. Usually, the larger the knife the more apparent this problem is. One other problem is that it removes material sideways along the edge, rather than coming towards it or away from it, which generally results in it only getting blades to moderately sharp. It's still a usable edge and done right it can typically still cut through a piece of paper.

If there are two smooth dark metal-looking pieces in the V, it is almost certainly Tungsten Carbide - which will eat away material very quickly. This is great for re-profiling an old rolled edge, and in fact, this is probably the only time I use one. The downside to Tungsten Carbide is that it eats away material very quickly - there won't be much blade left if used too often.

More recently it has become more common to find ceramic sharpening abrasives in pull-through sharpeners. Ceramic I feel is generally a good improvement over the Tungsten Carbide as it doesn't eat away nearly as much material. The downside to ceramic in this form is it is nearly impossible to clean. Over time ceramic gets gunked up with the metal shavings it removes and has to be cleaned to a new surface in order to be usable. In this format, it's nearly impossible to clean the ceramic material.

Sometimes you’ll find a pull-through sharpener on the back of a can opener or part of a kitchen knife set. Results on those can vary widely.

If you have small nicks in your blade, the V-Sharpener can smooth those out quickly. But some larger nicks get caught in the V, making the nick worse.

Pros

-

Many are small and easy to carry around

-

It's very easy to learn, anyone can learn how to do it

-

Puts a rough, serviceable edge on a knife

-

Very fast - Smooth out small nicks quickly

-

Inexpensive

-

Can be used to reintroduce an edge bevel to a blade or fixed a heavily rolled edge.

Cons

-

The edge is typically rather rough

-

Tungsten Carbide can eat too much of your blade away

-

Ceramic material cannot be easily cleaned

-

Has the potential to exacerbate nicks

-

Generally only achieves moderate sharpness

-

Depending on the device and your knife, you may not be able to sharpen the entire edge (guards & bolsters may prevent sharpening sections of the blade)

Conclusion

A V-Sharpener is a field sharpener and should be used as such. They are small and easy to carry with you in the field. The edge produced is rough, which is serviceable for a survival knife. They are very useful for reintroducing an Edge Bevel to your blade. In my opinion, the edge is not ideal and will have to be fixed once you are no longer in the field.

Take a look at AG's video on V-Sharpeners

Pull Through Options

Outdoor Edge Edge-X Pro - Has ceramic options which makes it my favorite version

CRKT Stokes Sharpener

SOG Desktop Sharpener

DMT Diamond-Vee Portable Sharpener

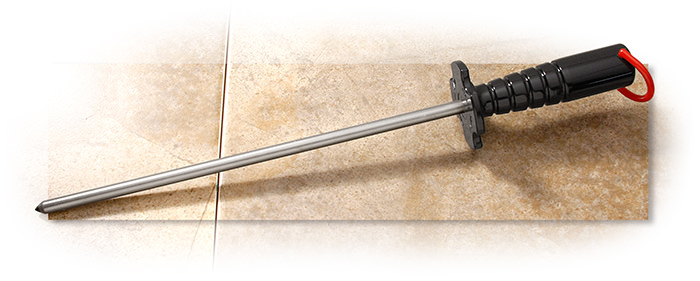

Hones, Kitchen Steels, and Butcher's Steels

A Honing Steel (or Hone), also known as a Kitchen Steel or Butcher's Steel, is a long rod of steel attached to a handle. There are three types of honing steel surfaces: smooth, ridge, and diamond coated. The smooth & ridged honing steel is made of hardened steel that does not actually sharpen your knife. Instead, it realigns the edge of your knife into a straight line and helps remove any egregious burrs - which in effect makes the blade sharper. Its effects are more noticeable on a butcher’s blade, which is usually made of softer steel. Once you have removed the burr too many times, the edge will be missing material, and the blade will be dull, and you'll need a sharpener that actually removes material to redress the edge.

The diamond coated honing steels will actually remove particles of steel and so will sharpen your knife, as well as help to align the edge. For those already comfortable with the use of a honing steel, a diamond one is the natural progression if actual sharpening is needed.

I'm sure you've seen movies where the chef holds the honing steel and quickly moves the blade back and forth over the rod in quick succession. With great experience, you can learn to do this as well. However, it is much safer and more accurate to place the hone straight up and down with the tip on the table or counter and hold the handle on the top. Then place your blade's heel at a 15 (typically) degree angle on the rod and stroke down the rod, repositioning to do it on both sides.

Pros

-

Very common

-

Easier to learn to use than bench stones

-

Moderately improves Cutting Ability

-

Looks good in your kitchen block

-

Relatively inexpensive

Cons

-

Regular hones do not actually remove any steel

-

Can’t fix a blade that is actually dull

Conclusion

Butcher’s steels do take a moderate amount of skill. They are easier to use than a bench stone, but not as easy as ceramic rods. Several of the Hones that we sell are actually coated in diamond dust, so they actually DO sharpen your blade.

In conclusion, Butcher’s Steels are certainly serviceable. If you are experienced in using them then they will continue to be serviceable. If you are looking for a new maintenance tool, I still stand by my main recommendation of using Ceramic Rods.

Options

Kershaw Sora Combination Honing Steel - Standard Honing Steel

DMT 12" Diamond Butcher's Steel - Uses diamonds to sharpen your knife

Strops

Strops are a flat piece of soft material (usually leather) with a little give to it. They are often glued to a piece of wood for stability, but the iconic straight razor strop you see in old barber shops has a metal hook and swivel instead (pictured on the right). Strops are similar to honing steels in that they do not sharpen the knife, they merely remove burrs. Strops are most often associated with straight razors. They work exceptionally well on straight razors because the edge is ground so incredibly thin. There are some folks in the knife community who will use strops along with a polishing compound to achieve a “super edge” or even a mirror-polished edge. Strops are a little divisive in the knife community. Many claim stropping is very important to the knife sharpening process. Others believe stropping to be an unnecessary step with limited, short-term results. Regardless of opinion, stropping can be an important step depending on what kind of sharpening process you are using.

Pros

-

Removes burrs from sharpening

-

Improves your edge

-

Compounds can be added to enhance your edge even further

-

Stropping can be very relaxing

-

Having a super edge that can slice a hair can be very satisfying

Cons

-

The results are generally short-term, gone within the first few uses of the knife

-

Strops do not remove steel and do not actually sharpen a knife

-

Unless you are using a straight razor, why do you need to slice a falling hair?

Conclusion

I am of the opinion that stropping, while nice, is typically an unnecessary step if you already have ceramic rods or other very fine abrasives. Although if your sharpening process produces significant burrs on your blade, then it is important to use a strop to remove them, even if that just means wiping it on smooth cardboard.

Options

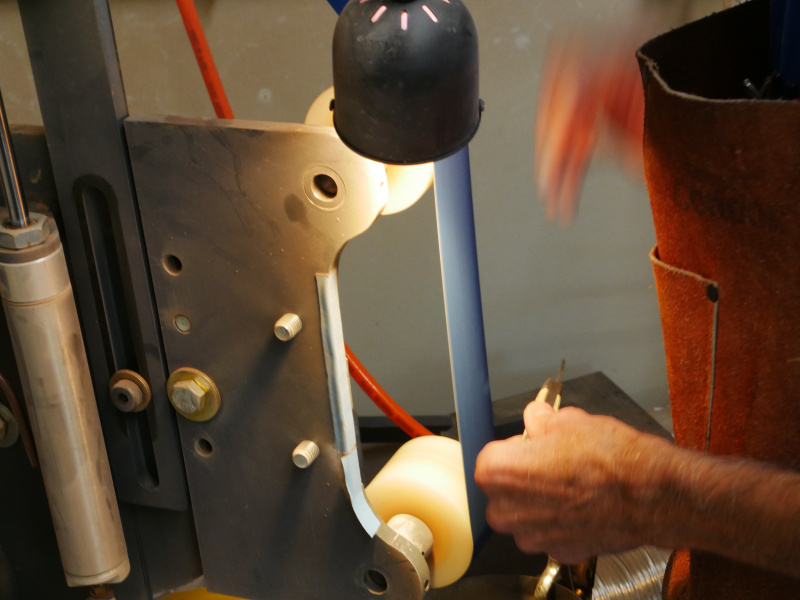

Belt Grinders

Belt Grinders are big belts of sandpaper and other abrasives and buffs that are attached to large motor-driven spinning wheels. 95% of all professional knife makers use belt grinders. They are fast, efficient, expensive, dangerous, and require skill to use.

The Worksharp has been introduced as a compact consumer model belt grinder for sharpening knives. It does its job, but there are things to consider. First, even with guided angles, it still takes a lot of practice. There are things to know. A good example is belt grinders take steel off so quickly that your blade needs to be moving before it ever touches the belt or you will take off too much metal at the heel.

Another point of consideration is the heat generated from friction. Friction from the fast-moving belt will heat up your knife quickly, and the thin steel blade edge can only heat up so much before the heat treatment is ruined and your knife will no longer hold its edge, no matter how sharp you get it.

Pros

-

The fastest and most efficient way to sharpen or shape knives

-

Achieves fantastic results

Cons

-

Can quickly ruin a blade

-

Requires a lot of practice and expertise

-

Dangerous

-

Expensive

Conclusion

Unless you intend to get into knife sharpening or making as a hobby or for employment, I do not recommend using a belt grinder. I have met quite a few customers who have ruined their knives using belt grinders. When you are first learning, you can typically expect to ruin at least 5-10 knives before you get the hang of it, and even after that you still have to be very careful. If you decide this is something you want to pursue, I suggest gathering a bunch of inexpensive kitchen knives. Check your local thrift store to find some practice knives for cheap.

Written by Jake Broce, advised by A.G. Russell III.

Updated 12/31/2019

Updated 6/10/2020

Updated 10/30/2020

Updated 7/7/2023