C

C-75

C-75 is a standard non-stainless carbon steel very comparable to 1075-1080. It will develop a blue-gray patina on the blade over time with use, which is typical and will help protect the blade from rust. You'll want to keep the blade clean and use something to protect the blade like Rust Free. C-75 is made in Germany, and has 0.7-0.8% Carbon (C), 0.6-0.8% Manganese (Mn), 0.15-0.35% Silicon (Si), 0-0.035% Phosphorus, and has a Rockwell of 55-58. This steel is heavily used by Boker.

California Buckeye

As the name indicates, this tree is a species of buckeye native to California with some appearing in southwest Oregon. It is the burl from the California Buckeye tree that is commonly used for knife handles. There are lots of voids in these burls, so a lot of waste. Recently, some suppliers have begun to use pieces of this wood, that would otherwise be burned, to create what some are calling ShokWood. Pieces of wood with interesting shapes are embedded in a resin to create a very interesting handle material.

California Clip Blade

A pocket knife blade with the clip beginning far back from the point perhaps one half inch from the handle.

Camillus Cutlery®

Established about 1875 and in the 1890s and early in the 20th Century made most of the really great knives now sought after by collectors. (Knives like the OVB and others). Today they are probably making the Remington knives; however, they also began making the OVB knives again. Good knives are generally much under rated.

Campers (See Scout, Utility)

This knife will have a Boy Scout Type Blade plus three utility blades

Canoe

A pocket knife with the handle ends curved up to make a canoe shape.

Caper

A knife designed to do the delicate work of skinning around the eyes and lips of trophy animals; this work is called caping because you are removing the cape of the animal.

Carbon

The mineral that transforms iron into steel. High-carbon steel results when .5 percent or more carbon is present. Only a bare .8+ can be absorbed by the iron, the balance in extremely high carbon steel goes to add hardness. Expressed as C.

Case Knife

An old time term much used by hunters until the 1940s now almost never used in the old meaning of a large folding knife or a fixed blade with a sheath. Today it would only be used to mean a knife made by the W. R. Case & Sons Company.

Case, W. R. & Sons

Case, W. R. & Sons

Once the most widely distributed of all American made pocket knives. Has passed through several hands in the past 20 years and is now making a comeback in the hands of the Zippo Lighter family. Look for real improvement. Shop W.R. Case knives here.

Cattlemans knife

A knife with a clip or spear master blade, a spey blade and a leather punch. Made with many handle shapes including an even end stock.

Ceramic

See Alumina Ceramic, and Zirconia

Champagne Pattern

Has a blade, a wire cutter and cork screw.

Chipped Flint

The first knives were probably broken pieces of flint or some other form or chert (jasper, agate, novaculite, quartz or other stone with a conchoidal fracture) exposing sharp edges. Many people are knapping flint in the old ways and some are fastening these blades into stag or wood handles.

Chital (see Axis - India Stag)

Chital (see Axis - India Stag)

The smaller of the two Indian and SE Asian deer that furnish antler for the knife industry; these are all shed horn harvested in the jungle by natives. Pictured is an adult male chital in hard antler in Kanha, Central India - Chital Picture Attribution.

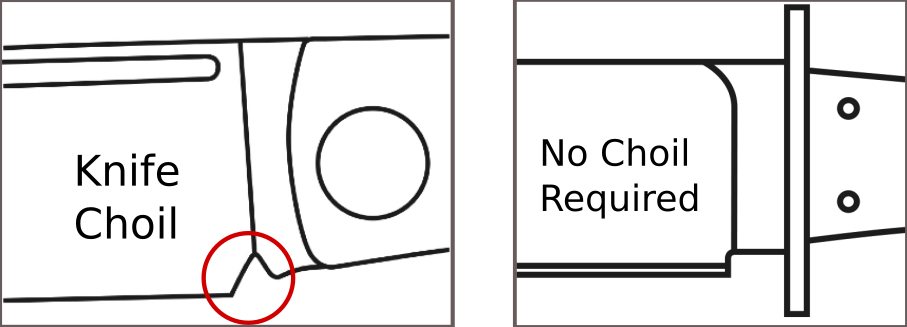

Choil

A choil is the cut away area, or notch, between the heel of the blade edge and the ricasso of a pocketknife blade and between the edge and the guard of a fixed blade knife.

For A.G., the reason for a choil simply had to do with the ability to sharpen the full length of the blade edge. In some instances a choil is not necessary because the blade is wider than the ricasso making it possible to sharpen the edge cleanly all the way to the heel. While a choil often adds to the visual appeal of a blade, that is not the reason for one to be used.

Chromium

Produces hardness and better edge holding when combined with other alloying materials. Used in fairly large amounts, it produces a blade that resists rust. Takes over 12.5% to produce high-carbon stainless steels. Expressed as Cr.

.jpg)

Cinquedea

A 15th Century Italian dagger, very wide at the hilt; usually used as a left hand dagger. Name means five fingers wide.

Citrus Tester (AKA Melon Tester/Fruit Tester)

Long slip pen blade or long slim spey, slim even end or swell center handle.

Clasp (Handle Shape)

Swell center front only, swell head, bolsters, caps one blade or two.

2%20-%20Requires%20attribution%20to%20Wikipedia%20Soren%20Niedziella.jpg) Claymore

Claymore

The two handed sword of the Scots from the 15th and 16th century. The Gaelic is "Claidheamh mor" which translates to "great sword." It had a long heavy blade, straight grip, small pommel, and straight quillons slanted towards the blade. The photo is an Albion replica of the claymore. Photo Credit: Søren Niedziella.

In later years, there was a Scotch broadsword of the 17th century that was based on the Venetian broadsword Schiavona. It was a basket hilted broadsword (one hand) that was favored by Scottish soldiers and officers. It was referred to as a "claymore", although many suspect this was erroneous naming from Victorian Scholars. It is still debated, but most tend to agree that the Claymore sword was indeed the two handed great sword initially described.

Clip Point Blade

A blade on which the back line breaks and slants downward to produce a finer and more useful point.

Cobalt

Increases strength and hardness, and permits quenching in higher temperatures. Intensifies the individual effects of other elements in more complex steels. Expressed as CO.

Coke Bottle (Handle Shape)

Swell Center, Top and Bottom, usually one blade

Collins, Blackie

Collins, Blackie

Founder of the Blade magazine and the most prolific inventor in today's knife world. Died July 20, 2011.

.jpg)

Congress Pattern

An old pen and pocket knife shape, made with two or four blades.generally a pen blade and a larger sheepfoot blade or two of each. The ends are lower than the center of the back of the handle.

Copper

Increases corrosion resistance. Expressed as CU.

Copperhead

A jack knife (blades are at a single end), usually with a primary Clip Point blade and a secondary pen blade. The pattern is also known for its distinctive bolster with a bulge that protects your pocket from the sharp Square End, or tang corners of the blades when they are shut.

Cordia wood

Cordia wood is very similar to Teak and is occasionally used as a substitute for Teak in shipbuilding.

Cotton Sampler

A special blade for cutting into cotton bales for samples.

CPM - Crucible Particle Metallurgy

Crucible Industries, a steel manufacturer, developed the proprietary Crucible Particle Metallurgy (CPM®) process in 1970 to produce high-speed tool steels. This process creates superior quality and higher alloy grade steels that cannot be made with conventional steelmaking.

Conventional Vs. CPM

Conventional Steelmaking begins by melting the steel down, refining it, and then pouring it into ingot molds. In the liquid state, the elements in the steel are uniformly spread throughout. As it slowly solidifies the alloying elements segregate together, which results in a less uniform microstructure. Milling processes are needed to break up and refine the microstructure, but the effects of the segregation are never fully undone. The higher the alloy and carbon content, the more noticeable these segregation effects are, which causing carbide clumping. Carbides are superhardened structures within steel that is hugely important for edge retention. When carbides clump up, the steel loses toughness (which increases the likelihood of chipping or breaking). This can also make it difficult to sharpen or have sections of steel that don't hold an edge as well.

The CPM process also begins with molten steel, but instead of going into ingots, it is poured through a small nozzle, and high-pressure gas bursts the liquid stream into tiny round droplets. These droplets rapidly solidify and are collected in powder form. This powder is much more uniform in alloy composition because it is solidified so quickly the elements do not have enough time to segregate. The powder is screened and then pressed into sealed vacuum steel containers. As it is pressed in forging level heat, the powder is bonded into a single piece with a much more homogeneous fine-grained microstructure (with a much more uniform distribution of carbides). It then undergoes the standard milling processes of conventionally made steel.

Advantages of CPM for the End-User

- Improved Wear Resistance (more edge retention)

- Improved Toughness (less chipping)

- Consistent Performance (less likely to have a clump of carbides making it prone to chipping or difficult to sharpen, or have a section empty of carbides resulting in terrible edge retention)

- Allows for higher grades steel with more alloys and carbon

- Excellent grindability (easier to machine, sharpen, and therefore less expensive to make - though the steel itself costs more than conventional steel initially)

- Often takes a better polish

- More consistent heat treatment

- More stable for coatings

- Efficient wire EDM cutting

CPM 10V

CPM 10V was the first in the family of high vanadium tool steels made by the Crucible Particle Metallurgy process. Crucible engineers optimized the vanadium content to provide superior wear resistance while maintaining toughness and fabrication characteristics comparable to D2 and M2. Since its introduction in 1978, CPM 10V has become recognized worldwide and sets the standard for highly wear resistant industrial tooling. Carbon (C) -2.45%, Manganese (Mn) -0.50%, Chromium (Cr) -5.25%, Vanadium-9.75%, Molybdenum (Mo) -1.30%. Rockwell 58-62

CPM 15V

CPM 15V is intended for applications requiring exceptional wear resistance. It has more vanadium carbides in its microstructure than CPM 10V and provides more wear resistance and longer tool life in those applications where 10V has proven to be successful. CPM 15V also offers an alternative to solid carbide where carbide fails by fracture or where intricate tool design makes carbide difficult or risky to fabricate.Carbon (C) -3.4%, Manganese (Mn) -0.5%, Chromium (Cr) -5.25%, Vanadium-14.5%, Molybdenum (Mo)-1.3%. Rockwell-59-62

CPM 1V

CPM (Crucible Particle Metallurgy) 1V is a medium carbon, high alloy tool steel which exhibits high toughness combined with high heat resistance. It is suited for hot or cold applications demanding high impact toughness that also requires moderate wear resistance. Carbon (C) -0.55%, Chromium (Cr)-4.5%, Vanadium-1.0%, Molybdenum (Mo) -2.75%, Tungsten (W) -2.15% Rockwell 56-59

CPM 3V

CPM 3V is a high toughness, wear-resistant tool steel made by the Crucible Particle Metallurgy process. It is designed to provide maximum resistance to breakage and chipping in high wear-resistance steel. CPM 3V is intended to be used at 58/60 HRC in applications where chronic breakage and chipping are encountered in other tool steels, but where the wear properties of high alloy steel are required. Carbon (C) -0.80%, Chromium (Cr) -7.50%, Vanadium (V) -2.75%, Molybdenum (Mo) -1.30%. Rockwell 58-60

CPM 9V

CPM 9V is designed for use in tooling that encounters severe wear. Its toughness, or cracking resistance, is higher than other high-wear resistant cold work tool steels permitting it to be used in some applications where CPM 10V, D2 or high-speed steels do not have sufficient resistance to cracking. It is usually limited in hardness to about 56 HRC or lower, and is therefore not intended for applications requiring high compressive strength. Carbon (C) -1.8%, Manganese (Mn) -0.50%, Chromium (Cr) -5.25%, Vanadium (V) -9.0%, Molybdenum-1.3% Rockwell 53-56

CPM-M4

A powdered high speed non-stainless tool steel from Crucible. It has high wear resistance and high impact toughness, making it popular for cutting competition knives. It has a higher toughness than M2, and is mainly used in custom knives, although Benchmade and Spyderco have made a few sprint runs with it. It is a high end tool steel and is fairly expensive.

1.40% Carbon (C), 4.0% Chromium (Cr), 0.30% Manganese (Mn), 5.25% Molybdenum (Mo), 0.55% Silicon (Si), 0.06% Sulphur (S), 5.50% Tungsten (W), 4.00% Vanadium (V).

CPM-S30V®

CPM-S30V (commonly referred to as S30V) was introduced by Crucible in 2002 in response to demand from the knife industry for a steel with more wear and corrosion resistance and more toughness. It has vanadium added for higher wear resistance and more molybdenum for better pitting resistance. It is also more resistant to edge chipping with superb edge retention. Contains about 1.45% Carbon (C), 14% Chromium (Cr), 2% Molybdenum (Mo), and 4% Vanadium (V).

CPM-S35V®

CPM-S35VN is a variation of CPM-S30V with slightly altered elements to improve its toughness. The Vanadium is lowered by 1%, and 0.5% of Niobium is added. This change makes CPM-S35VN about 15-20% tougher than CPM-S30V without any loss of wear resistance. It is also easier to machine and polish can CPM-S30V. It is resistant to edge chipping with superb edge retention. Contains about 1.40% Carbon (C), 14% Chromium (Cr), 2% Molybdenum (Mo), and 3% Vanadium (V), and 0.50% Niobium (Nb).

CPM-S45VN®

CPM-S45VN is one of the newest steels on the block (New for fall of 2019), but is already becoming popular with knifemakers. Chris Reeve, Buck Knives, Spartan Blades, and Spyderco all already have blades made with CPM-S45VN. It is a variation of CPM-S35VN but with rebalanced chemistry. It adds additional chromium to form more chromium carbides and leave some more free Chromium (free Chromium is necessary for rust resistance). CPM-S45VN offers slightly improved wear resistance over CPM-S35VN. It has similar toughness (slightly below S35VN and slightly above S30V), but it has significantly better Corrosion Resistance than either.

Contains about 1.48% Carbon (C), 16% Chromium (Cr), 2% Molybdenum (Mo), 3% Vanadium (V), and 0.50% Niobium (Nb), and 0.15% Nitrogen (N).

CPM-S60V® (New Name for CPM440V)

2.15% Carbon (C), 0.4% Manganese (Mn), 17% Chromium (Cr), 5.5% Vanadium (V), and 0.4% Molybdenum (Mo).

Definition:A unique tool steel made by the Crucible Particle Metallurgy process.. It is designed from a 440C stainless base with added carbon and Vanadium for exceptional wear resistance and good corrosion resistance. An excellent candidate to replace ATS-34 and 154-CM.

CPM-S90V®

An American steel from Crucible, CPM-S90V is one of the top super steels of today. It features incredible edge retention and wear resistance, and very high corrosion resistance. It is a very expensive steel, and only comes in top of the line knives. CPM-S90V's extreme wear resistance is due the incredible amount of Vanadium in the alloy, and as a result it can be very difficult to grind or sharpen.

2.3% Carbon (C), 14% Chromium (Cr), 9% Vanadium (V), and 1% Molybdenum (Mo). Typically Rockwells at 56-59 Rc.

CPM-S110V®

An American steel from Crucible, CPM-S110V is one of the top super steels of today and is cousin to CPM-S90V. It features incredible edge retention and wear resistance, and very high corrosion resistance. It is a very expensive steel, and only comes in top of the line knives. CPM-S110V's extreme wear resistance is due the incredible amount of Vanadium in the alloy, and as a result it can be very difficult to grind or sharpen.

CPM-S110V is a high-alloy martensitic stainless tool steel manufactured by the Crucible® Particle Metallurgy (CPM) process. This process begins with a homogenous molten bath of high-alloy steel that is forced through a nozzle under high-pressure nitrogen gas to create a spray of small spherical droplets that quickly solidify into powder particles. The small size of the particles forms micro-ingots, drastically reducing the alloy segregation in the steel and ensuring an extremely fine carbide microstructure when the powder is processed into finished steel.

Carbon (C) 2.8%, Chromium (Cr) 15.25%, Vanadium (V) 9%, Molybdenum (Mo) 1%, Niobium (Columbium) 3.0%, and Cobalt 2.50%. Typically Rockwells at 58-61 Rc.

CPM440V

With 2.15 Carbon (C), 0.40 Manganese (Mn), 17.0 Chromium (Cr), 5.50 Vanadium (V) and 0.4% Molybdenum (Mo) this is a steel that would be impressive but when you know that it is a Powder Metal steel with the resulting extreme purity, you know that it has to be a great knife steel. Very expensive and not at all easy to work.

CPM-CruWear

CruWear is an air-hardening tool steel, which can achieve a Rockwell hardness of 60-65 Rc. It was made as an upgrade to D2, offering better wear resistance, much better toughness, and hardness.

Carbon (C) 1.1%, Chromium (Cr) 7.5%, Vanadium (V) 2.4%, Tungsten (W) 1.15%, Molybdenum (Mo) 1.6%.

CTS® BD1

An American steel by Carpenter, CTS-BD1 is a vacuum-melted stainless steel that is highly corrosion resistant and holds a good edge. It is sometimes likened to AUS-8 or 8Cr13MoV, but with slightly better edge holding. It is relatively easy to sharpen, and the carbides are medium sized.Carbon (C) 0.90%, Chromium (Cr) 15.50%, Manganese (Mn) 0.60%, Molybdenum (Mo) 0.30%, Silicon (Si) 0.37%, Vanadium (V) 0.10%. Typical Rockwell of 58-60 Rc.

CTS® BD1N

Carpenter® CTS® BD1N alloy is a nitrogen-bearing, high-carbon chromium martensitic steel that is balanced to provide superior hardness capability to CTS BD1. In terms of performance, it can be comparable to Japanese VG-10.

With 0.85-0.95 Carbon (C), 1.0 Manganese (Mn), 0.30 Phosphorus, 0.01 Sulfur, 1.0 Silicon (Si), 15.0-17.0 Chromium, 0.5 Molybdenum (Mo), and 0.10-0.15% Nitrogen, this is a steel that can resist corrosion from mild atmospheres, fresh water, steam, ammonia, many petroleum products and organic materials. With a capability of HRC 60-63.

CTS-40CP

An American steel from Carpenter, CTS-40CP is essentially Carpenter's version of 440C.

Carbon (C) 0.95-1.20%, Chromium (Cr) 16.00-18.00%, Manganese (Mn) 1.00%, Molybdenum (Mo) 0.75%, Silicon (Si) 1.00%. Typical Rockwell of 59-60 Rc.

CTS-XHP

An American steel from Carpenter, CTS-XHP is a stainless steel with great edge retention. You can almost think of it like D2, but with more corrosion resistance. It can be difficult to sharpen and like D2 it can be a little and prone to chipping on the edge.

Carbon (C) 1.60%, Chromium (Cr) 16.00%, Manganese (Mn) 0.50%, Molybdenum (Mo) 0.80%, Nickel (Ni) 0.35%, Silicon (Si) 0.40%, Vanadium (V) 0.45%. Typical Rockwell of 58-60 Rc.

Crink

A slight bend at the tang in a knife with two or more blades that allows the blades to close without touching.

Crooked Jack (Handle Shape)

Today called a dog leg Jack.

Crown (Handle Shape)

Originally the crown pattern was a square end cigar pattern. The modern cigar is a square, even end pattern.

Cryogenic Quench

A modern addition to heat treating tool steels. After the normal heat treat the steel is lowered in temperature very low. Before it became widely available with heat-treating firms many makers were using liquid nitrogen and doing it at home.

Curved Jack (Handle Shape)

The handle curves up to the blade.

Curved Regular Jack (Handle Shape)

The handle curves down to the blades.

Custom Knife

The following paragraph is the correct meaning of Custom Knife, however in today's knife world it means a knife not made in a factory, it can be handmade or assembled from mass produced parts. Today the term is totally without meaning.

A Custom Knife is one in which the customer has either designed all or part of the knife OR a knife in which the customer has specified the materials in a makers own design. Selecting one of the listed handle materials in a makers catalog to be put on a blade of the makers design does not make a custom knife.

Cutlass

A curved blade sword sharp on one edge with a strong cover for the hand used on naval vessels in the 18th and 19th Centuries.

Cutlery Steel

Any steel with enough alloying materials that enable it to make good knives; for wide acceptance today that means it must also be stainless. To make good knife blades it must be able to take and hold an edge. Can range from 1070 or 420 to CPM-S90V.