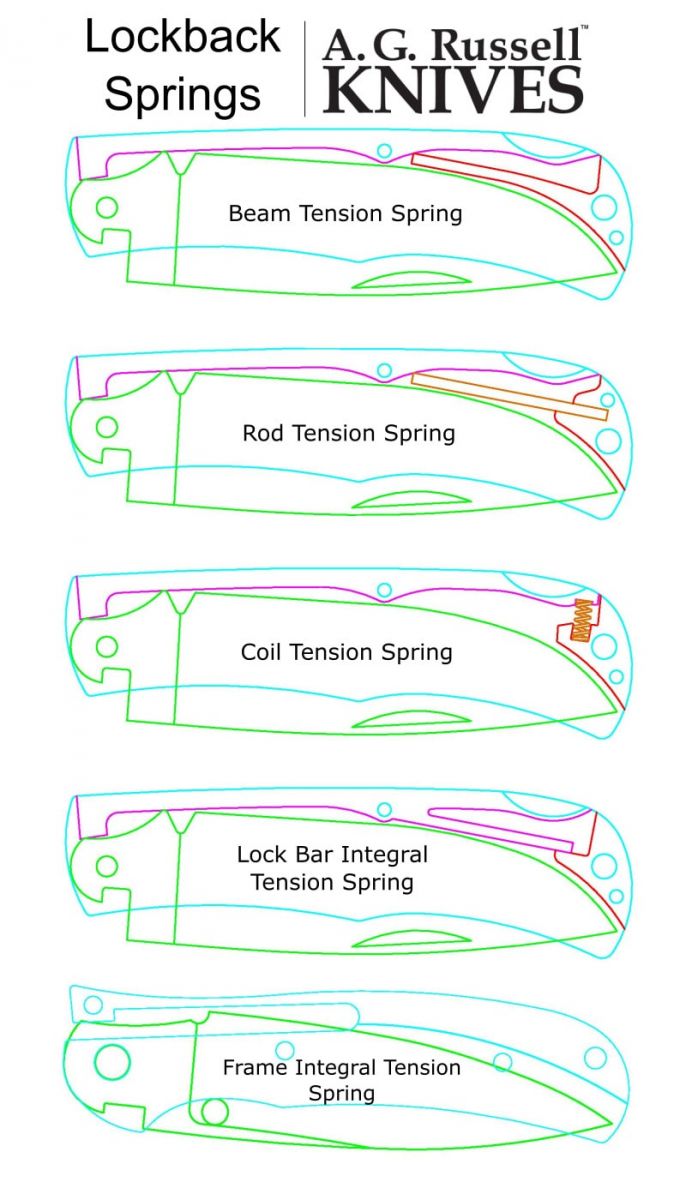

5 types of Lockback Springs

Let me talk to you about some different types of Lockback Springs. I’ll go over five: the Beam Tension Spring, Rod Tension Spring, Coil Tension Spring, Lock Bar Integral Spring, and Frame Integral Tension Spring. By no means is this a complete list of springs, but these are some of the more popular or unique ones. I have used each of these springs in one knife or another, with the exception of the Lock Bar Integral.

Let me talk to you about some different types of Lockback Springs. I’ll go over five: the Beam Tension Spring, Rod Tension Spring, Coil Tension Spring, Lock Bar Integral Spring, and Frame Integral Tension Spring. By no means is this a complete list of springs, but these are some of the more popular or unique ones. I have used each of these springs in one knife or another, with the exception of the Lock Bar Integral.

Let me start by saying that each of these springs are merely different. One isn’t significantly better than another in many concrete ways. The way a designer chooses a spring is based mainly on the shape of the handle and the shape of the blade. Different springs will fit or work better with different style knives. As a general rule, the spring does not affect the strength of blade’s lock up, if done properly. The strength of the lock up, how much pressure the lock can take before something breaks, has more to do with the materials and the methods and tolerances of manufacture.

The image below shows the same knife blade and handle to illustrate the different types of springs. In reality your choice of spring would depend on how you wanted the blade and handle shaped.

Beam Tension Spring

One of my knives that uses the Beam Tension Spring is the 2015 Texas Ranger knife.

The Beam Tension Spring is very similar to the Rod Tension Spring. Usually the deciding factor between the two is what kind of factory set up you have. The Beam Tension Spring is made through blanking in the manufacturing process. This is the old school style of manufacturing. Newer factories using CNC or laser cutting processes will usually opt for the Rod Tension Spring. One is not better than the other, just different processes.

Camillus was excellent at blanking. The advantage of the Beam Tension Spring is that it can be tapered, saving room. Breakpoints can be strengthened by widening the material at that point. Because blanking is limited to certain stock sizes, Camillus would blank a set of two Beam Tension Springs and put them into the knife side by side. Rather ingenious.

Rod Tension Spring

.jpg)

An example of the Rod Tension Spring is the Bob Loveless designed Gentleman’s Folder.

Rod Tension Springs are probably the most prominent of the lockback springs. To make a mid-lock, you would use a Rod Tension Spring.

Spyderco and Buck both use the Rod Tension spring extensively. Spyderco for their mid-locks, and Buck in their Buck 110s.

Coil Tension Spring

My Lockback Folding Hunter is a good example of the Coil Tension Spring.

The Coil Tension Spring is a bit rarer. You do not see many manufacturers using them. There are a number of handmade makers who use them. They cannot be used in a mid-lock because they take up too much room. The Coil Springs can be a bit finicky, and require the designer and maker to know what they are doing. Done properly they can be excellent.

Lock Bar Integral Spring

I have never used this spring. It’s harder to make, and requires a bit of finesse. That being said, I have held custom Tony Bose knives with the Lock Bar Integral Spring inside, and it was extremely well done. Very well made, very smooth, an excellent knife all around.

The Lock Bar Integral Spring is pretty rare, and mostly used in custom knives.

Frame Integral Tension Spring

The K87 is a prime example of the Frame Integral Tension Spring. This is the most difficult spring to make. Incredibly so. It is, in fact, an engineering marvel. We have made the K87 in the U.S., and also in Japan. We have finally come out with new ones from expert knife makers in Italy. It is a long and costly process to make, which is why they are not very common.

.jpg)